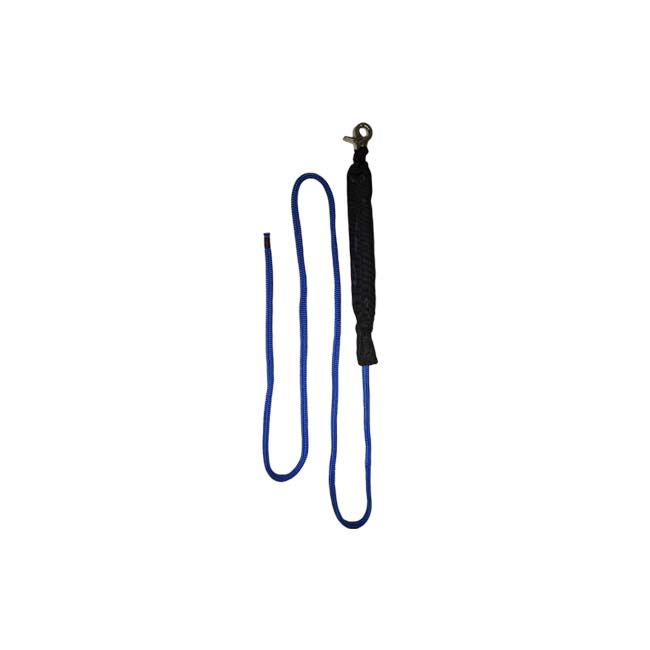

8-Strand

Plaited Ropes

US Made Anchor Rope

We believe that 8 Plait polyester is the best choice for anchor rode,

and Buccaneer Rope Company makes a premium product

Polyester offers higher strength, better abrasion resistance and better UV resistance than nylon. Polyester rope does have less stretch than nylon but when used in longer lengths ( > 50) feet, it has adequate stretch to absorb the shock loading from waves and wind gusts. If anchor rode is a chain-line hybrid, and the conditions require deploying line rode in addition to the chain, we recommend deploying ≥ 50 feet of line to make sure you have adequate shock absorption.

8-strand braid is generally smoother and less prone to twisting or kinking, making it easier to store and deploy.

The braided construction of an 8-strand line reduces the likelihood of the rope becoming tangled or twisted when stored.

Windlass compatibility

Chain Size | Line Size | Recommended Splice |

1/4″ Chain (6mm) | 1/2″ (12mm) | Back splice |

5/16″ Chain (8mm) | 9/16″ (14mm) | Back splice |

3/8″ Chain (10mm) | 5/8″ (16mm) | Back splice |

1/2″ Chain (12mm-13mm) | 3/4″ (20mm) | Back Splice |

Line Rode on a chain gypsy:

Vertical Windlass offers Advantages for Line Handling over the Horizontal Windlass:

- Greater Wrap Angle: On a vertical windlass, the rope typically makes a near 180-degree wrap around the chain gypsy. This larger contact area provides significantly better grip and reduces slippage when hauling or deploying a rope/chain rode.

- Improved Control: The increased grip translates to more controlled handling of the line, making it less likely to jump or snag.

- Often Includes a Capstan: Many vertical windlasses are available with a capstan on top of the gypsy. This additional drum is specifically designed for handling mooring lines and can also be used to assist with the anchor rode, providing even better control and the ability to use the line independently of the chain.

- Better Alignment: The vertical orientation often allows for a straighter lead of the rope from the bow roller to the gypsy, minimizing friction and potential for chafe.

Horizontal Windlass Considerations for Line Handling:

- Limited Wrap Angle: Horizontal windlasses typically have a much smaller wrap angle (around 90 degrees) on the gypsy for the rope. This reduced contact area can lead to less secure grip and a higher chance of slippage, especially under load.

- More Reliance on Spring-Loaded Fingers: Horizontal windlasses often rely more heavily on spring-loaded fingers or snubbers to help the gypsy grip the rope. While these can be effective, they are mechanical parts that can wear or malfunction.

- Alignment Critical: Precise alignment between the bow roller and the horizontal gypsy is crucial for smooth rope handling. Off-center leads can cause significant friction and wear.

- Separate Drum Often Required: To effectively handle rope with a horizontal windlass, a separate warping drum is often necessary. This adds to the windlass’s footprint on deck and requires the rope to be manually led to the drum. Getting the rope to then feed neatly into the chain pipe can also be an issue.

In summary:

While both vertical and horizontal windlasses can handle rope spliced to chain, vertical windlasses generally offer superior performance and more secure handling of the line due to the greater wrap angle on the gypsy and the availability of a capstan.

However, it’s crucial to:

- Check the manufacturer’s specifications: Always verify that the specific windlass model you are considering is designed to handle the type and size of rope you intend to use.

- Ensure proper splicing: A well-executed splice that transitions smoothly is essential for both types of windlasses, if you need to splice your chain to line rode you we can do that for you.

Ultimately, if you plan to use a significant amount of rope in your anchor rode, a vertical windlass designed for rope/chain combination will likely provide a better and more reliable experience. Sources and related content

Rope Safety Considerations

New Rope Tensile Strengths: New rope tensile strengths are based on tests in accordance with ASTM Test Method D-4268 on new and unused rope in laboratory condition.

Working Loads: Working loads are for rope in good condition with approximate splices, in non-critical applications, under normal service conditions. Working loads should be exceeded only with expert knowledge of conditions and professional estimates of risk. Working loads should be reduced where life, limb, or valuable property is involved, or for exceptional service conditions such as shock loads, sustained loads, etc.

The Cordage Institute specifies that the Safe Working Load of rope shall be determined by dividing the Minimum Tensile Strength by the Safety Factor. Safety factors range from 5 to 12 for non-critical uses.

OD (in) | OD (mm) | Ultimate Tensile Strength (lbs) |

|---|---|---|

1/2 | 12 | 7,700 |

9/16 | 14 | 9,900 |

5/8 | 16 | 12,100 |

3/4 | 19 | 15,200 |

CALL US WITH ANY QUESTIONS:

WITHIN THE US: 1-855-262-6887

BEYOND THE US: 469-226-3468 / 469-878-4083